Katun DPS® and Sustainable Technology

Katun DPS® is committed to taking the most sustainable approach to industrial printing. That's why, the company only aligns itself with suppliers and distributors that comply with its standards for sustainable practices. From reduced CO2 emissions to reforestation programs, the environment is a main pillar of our policy. With that said, Katun DPS® takes this commitment one step further to prioritize including machines that are built in the most environmentally conscious way.

Beginning by leading the industrial transition from toner to inkjet is the first step in our program. This would also ensure that all packaging labels are completely safe for print on food and beverage consumables. Moreover, embedded in the high-quality standards of Katun DPS®, the company strictly only selects printers with long-lasting printhead technology, such as Memjet's Duraflex®.

Katun DPS® and Memjet Duraflex®: A Match in Practice

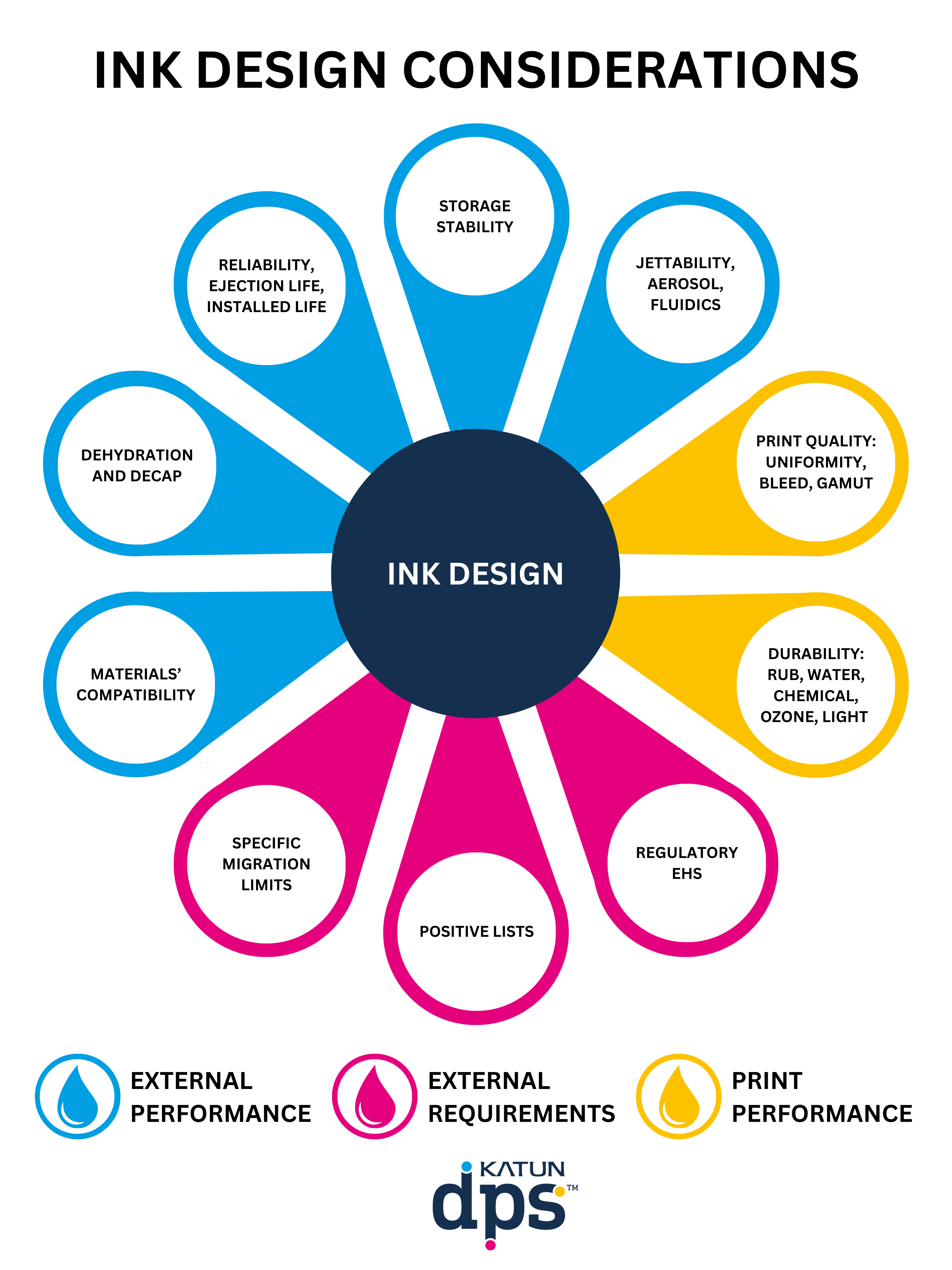

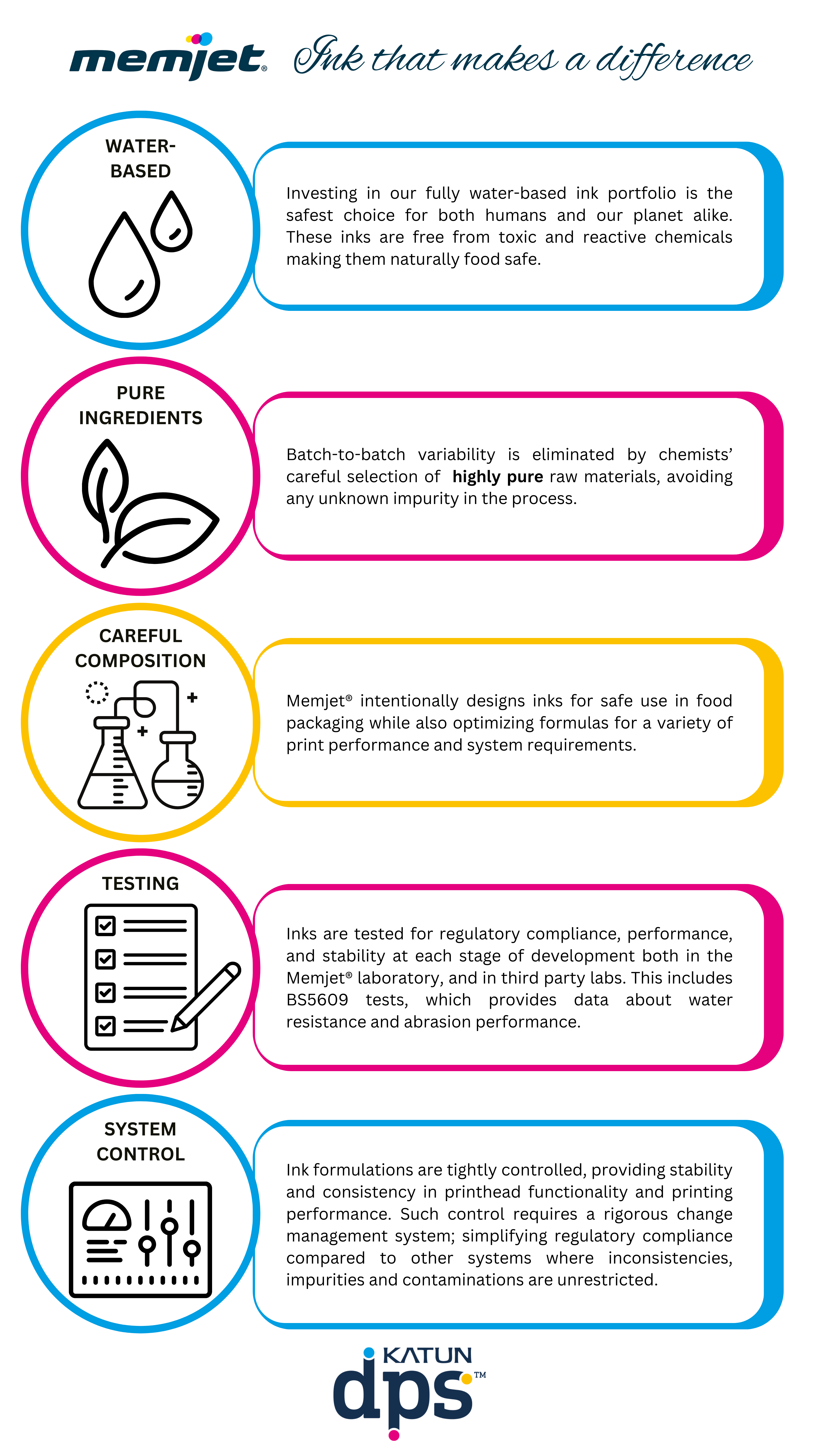

DuraFlex®'s innovative approach to ink formulation is setting new standards for environmental sustainability and safety in food packaging. The unique properties of Memjet inks are designed specifically for food packaging applications, emphasizing their commitment to health and environmental safety.

One of the standout aspects of Memjet ink technology found in Katun DPS® printers is its low migration properties. This is crucial in food packaging, as it minimizes the risk of ink components transferring onto the food. These inks are carefully formulated with high molecular weight components that are less likely to migrate, ensuring that the packaging remains safe and contamination-free.

Environmental Sustainability and Certified Consumer Safety

Katun DPS® commits to complying with stringent global safety standards is evident in our rigorous selection protocols. All inks the company uses undergo extensive migration testing to ensure they meet the safety criteria set by international food safety regulations, including the Swiss Ordinance and FDA guidelines. This adherence to safety standards reassures consumers and businesses alike of the quality and safety of the packaging.

The core feature of inkjet technology is its water-based composition, which significantly reduces the environmental impact compared to solvent-based inks. These inks are free from volatile organic compounds (VOCs), heavy metals, and other hazardous substances that are often found in traditional inks, making them a safer choice for both the environment and human health.

Responsible Manufacturing and Distribution: Results and Conclusions

The ink testing and selection process is further filtered through the ink's current or potential recyclability. The inks are designed to be easily deinked, which facilitates recycling processes and supports the circular economy. This aligns with the commitment made by Katun DPS® towards innovation and responsible manufacturing.

By combining advanced ink chemistry with a strong emphasis on environmental and health safety, these inks offer a sustainable and safe solution that meets the demands of the modern food industry.